Advanced Rpz Valve Testing Technologies

Rpz valve testing is a critical process for ensuring the proper function and safety of valve systems used in various industrial applications. Accurate testing helps identify potential issues before they lead to failures, reducing downtime and maintenance costs. The testing process involves detailed inspection, pressure testing, and operational checks to verify valve integrity and performance.

Statistics indicate that regular Rpz valve testing can extend the lifespan of valves by up to 30%, while also improving operational efficiency. Professionals typically complete comprehensive testing within a few hours, depending on the complexity and number of valves involved. Proper testing protocols are essential for compliance with safety standards and to prevent costly system failures.

Professional Rpz valve testing generally takes between 2 to 4 hours per valve, depending on the system's complexity and size.

The process includes visual inspection, pressure testing, operational checks, and leak detection to ensure valves meet performance standards.

Hiring experienced technicians ensures accurate results, reduces risk of system failure, and maintains compliance with safety regulations.

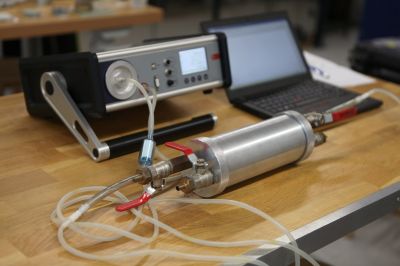

Properly conducted Rpz valve testing involves multiple steps, starting with a thorough visual inspection to identify any visible damage or wear. This is followed by pressure testing, where the valve is subjected to specific pressure levels to verify its sealing capability. Operational tests assess the valve's responsiveness and movement, while leak detection ensures no unintended fluid escape occurs. These procedures collectively confirm the valve's readiness for operational use.

Engaging a professional for Rpz valve testing guarantees adherence to industry standards and ensures comprehensive evaluation. Skilled technicians utilize specialized tools and follow established protocols to detect issues that may not be visible during routine inspections. This proactive approach minimizes the risk of unexpected failures, enhances system reliability, and optimizes operational performance.

The final stage of Rpz valve testing involves reviewing test results, documenting findings, and recommending necessary repairs or adjustments. Visual documentation of the testing process and completed work can assist in future maintenance planning and compliance audits. Proper documentation ensures transparency and accountability in the testing procedure.

For those interested in scheduling Rpz valve testing or obtaining a detailed quote, filling out the contact form provides a straightforward way to connect with qualified professionals. Accurate information about the system and testing requirements helps facilitate efficient service planning and execution.