Rpz Valve Testing Schedule Guidance

Rpz Valve Testings are essential for ensuring the reliability and safety of pressure relief systems. Conducting these tests at optimal times can prevent failures, reduce downtime, and maintain regulatory compliance. Proper timing depends on operational conditions, system usage, and manufacturer recommendations.

Perform Rpz Valve Testings during scheduled maintenance to verify performance and identify potential issues before critical failures occur.

Test valves immediately after installation to ensure correct setup and functionality according to specifications.

Conduct testing before starting new or restarted systems to confirm valves are operational and ready for use.

Test valves following any system modifications or repairs to verify integrity and proper operation.

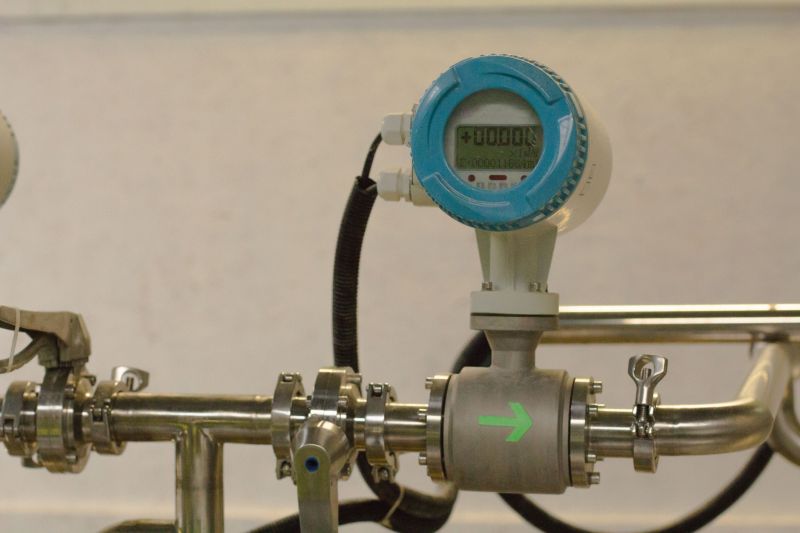

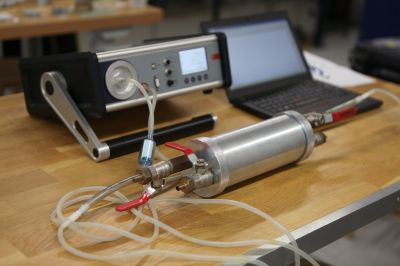

Specialized tools used to perform accurate and reliable Rpz Valve Testings.

Technicians conducting Rpz Valve Testings to ensure system safety and performance.

Visual and functional inspections after Rpz Valve Testing to confirm proper operation.

Protective equipment used by technicians during Rpz Valve Testings for safety compliance.

| Timing Aspect | Details |

|---|---|

| Scheduled Maintenance | Perform at regular intervals based on manufacturer recommendations. |

| Post-Installation | Test immediately after installing new valves. |

| Pre-Operational | Check before system starts or restarts. |

| Post-Repair | Verify after repairs or modifications. |

| Environmental Stability | Choose periods with stable environmental conditions. |

| Regulatory Compliance | Align with industry testing intervals. |

| Operational Downtime | Schedule during low activity periods. |

| System Upgrades | Test after major system upgrades or expansions. |

Rpz Valve Testings are critical for maintaining system integrity and safety. They help detect potential failures early, ensuring pressure relief systems function correctly under various conditions. Regular testing also supports compliance with safety standards and prolongs the lifespan of valves.

Technicians performing Rpz Valve Testing in a controlled environment.

Proper setup of testing tools to ensure accurate results.

Inspection reports showing test outcomes and valve condition.

Use of protective gear and safety protocols during testing procedures.

Ways to make Rpz Valve Testings work in tight or awkward layouts.

Popular materials for Rpz Valve Testings and why they hold up over time.

Simple add-ons that improve Rpz Valve Testings without blowing the budget.

High-end options that actually feel worth it for Rpz Valve Testings.

Interested in scheduling Rpz Valve Testings or learning more about the process? Filling out the contact form provides a straightforward way to initiate a consultation or request additional information.